Exhibitor and partner directory

08/21/2025

E-Mobility - Safety Simplified – Intelligent Safety Solutions for Battery Systems

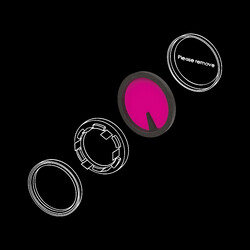

Complex battery systems in e-mobility place the highest demands on space, functionality and safety. To meet these requirements, Konzelmann GmbH has developed a modular system that flexibly integrates safety-relevant functions such as pressure equalization and emergency degassing.

At the heart of this system is the KBerstring®, a solution based on high-performance polymer components that can be integrated into battery housings in a space-saving and cost-effective way. Combined with gas-tight VentiKon membranes, which impress with high water resistance and temperature stability from −40°C to +80°C, both burst pressure and pressure equalization can be tailored to the requirements of each individual system.

Modular principle for maximum flexibility

The modular system allows different integration methods: The KBerstring® can be directly integrated into the housing using laser welding, ultrasonic welding or adhesive bonding. Where this is not possible – for example, due to material restrictions, manufacturing constraints or later integration – additional housing modules, fastening elements and seals are used. These make it possible to insert, screw or snap the functional unit into place – depending on installation position, choice of material and production process.

Safety by design

Each individual safety element at Konzelmann is 100 percent tested and marked with a unique laser code. This ensures complete traceability – a key quality feature for safety-critical applications. Thanks to standardized test methods and the use of ROBB test bodies (Rupture, Opening, Bursting, Breathing), the behavior of the safety element within the system can be predicted at an early stage.

Customer benefits at a glance:

•

Flexibility: Adaptable to different installation scenarios and manufacturing processes

•

Efficiency: Fast implementation with reduced development and testing effort

•

Safety: Maximum traceability through complete testing and laser coding

•

Sustainability: Modular design enables re-use of validated functional units

“Our modular solutions built around the KBerstring® stand for maximum safety with minimal integration effort. By combining a robust functional unit with an adaptable modular system, we enable

customized safety concepts that are fast to implement and economically feasible – even under demanding conditions,” explains Dr André Konzelmann, CEO and Head of eMobility Business Unit at Konzelmann.

Would you like to learn more about Konzelmann’s intelligent safety solutions for battery systems or are you interested in an interview? Please contact our press office.

At the heart of this system is the KBerstring®, a solution based on high-performance polymer components that can be integrated into battery housings in a space-saving and cost-effective way. Combined with gas-tight VentiKon membranes, which impress with high water resistance and temperature stability from −40°C to +80°C, both burst pressure and pressure equalization can be tailored to the requirements of each individual system.

Modular principle for maximum flexibility

The modular system allows different integration methods: The KBerstring® can be directly integrated into the housing using laser welding, ultrasonic welding or adhesive bonding. Where this is not possible – for example, due to material restrictions, manufacturing constraints or later integration – additional housing modules, fastening elements and seals are used. These make it possible to insert, screw or snap the functional unit into place – depending on installation position, choice of material and production process.

Safety by design

Each individual safety element at Konzelmann is 100 percent tested and marked with a unique laser code. This ensures complete traceability – a key quality feature for safety-critical applications. Thanks to standardized test methods and the use of ROBB test bodies (Rupture, Opening, Bursting, Breathing), the behavior of the safety element within the system can be predicted at an early stage.

Customer benefits at a glance:

•

Flexibility: Adaptable to different installation scenarios and manufacturing processes

•

Efficiency: Fast implementation with reduced development and testing effort

•

Safety: Maximum traceability through complete testing and laser coding

•

Sustainability: Modular design enables re-use of validated functional units

“Our modular solutions built around the KBerstring® stand for maximum safety with minimal integration effort. By combining a robust functional unit with an adaptable modular system, we enable

customized safety concepts that are fast to implement and economically feasible – even under demanding conditions,” explains Dr André Konzelmann, CEO and Head of eMobility Business Unit at Konzelmann.

Would you like to learn more about Konzelmann’s intelligent safety solutions for battery systems or are you interested in an interview? Please contact our press office.

Downloads

Contact for press inquiries

Press contact Press office Konzelmann c/o follow red GmbH Dimitra Malama

Waldburgstraße 17/19 70563 Stuttgart Germany Tel.: +49 (0)173 2835973 E-mail: [email protected]

The images provided can only be used in connection with reporting on Konzelmann, quoting “Photo: Konzelmann”.

Waldburgstraße 17/19 70563 Stuttgart Germany Tel.: +49 (0)173 2835973 E-mail: [email protected]

The images provided can only be used in connection with reporting on Konzelmann, quoting “Photo: Konzelmann”.

Further press releases of the exhibitor

Polymer Expertise - “Innovation meets Polymer” – Polymer Expertise that Drives Change

PRESS KIT – Company Profile - Global Expertise, Swabian Roots – Konzelmann in Portrait

PRESS KIT – Introduction - Innovation meets Polymer – Konzelmann at IAA MOBILITY 2025

TPU – Sustainable Material Expertise for the Mobility of Tomorrow

◦

◦

◦

◦