Exhibitor and partner directory

08/21/2025

TPU – Sustainable Material Expertise for the Mobility of Tomorrow

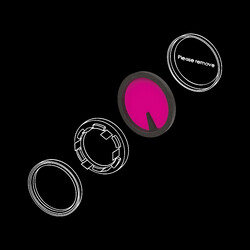

With the establishment of its own competence center for thermoplastic polyurethanes (TPU) at its headquarters in Löchgau (Germany), Konzelmann GmbH has reached a strategic milestone. The goal is to develop customized high-performance seals for demanding applications in automotive engineering, hydraulics, pneumatics and industry.

Advantages of TPU

The injection molding process for TPU enables properties that cannot be achieved with conventional seals made of metal, rubber-metal or PTFE:

•

Implementation of complex geometries

•

Short production cycle times

•

Lightweight design potential through the substitution of heavier components

•

Simplified assembly thanks to flexible, installation-friendly geometries

“Thanks to our experience with complex sealing applications and the highly robust TPU material, we are able in some cases to replace a complicated metal or rubber-metal sealing solution with a pure TPU solution – achieving noticeable weight reduction while simultaneously optimizing vehicle performance,” explains Heiko Kurz, Head of Sealing Technology Business Unit at Konzelmann.

Focus on sustainability

Konzelmann pursues a clear sustainability approach with TPU. Wherever technically feasible, materials are developed using renewable raw materials – such as castor oil. Results are continuously validated in the company’s own chemical laboratory. At the same time, Konzelmann completely avoids prohibited substances or PFAS.

“For us, thermoplastic polyurethane (TPU) is a biogenic high-performance material class that not only convinces ecologically but also represents a superior alternative to conventional plastics,” emphasizes Heiko Kurz.

New applications in mobility

Alternative drive concepts are opening up new application possibilities for TPU: in electric and fuel cell vehicles, operating temperatures are significantly below the maximum continuous temperature of 110°C. This allows TPU seals to be used in areas where they were previously unsuitable due to thermal stress.

Outlook: Hydrogen technology

Applications in the hydrogen sector with pressures up to 1,050 bar and temperatures down to −60°C are particularly challenging. Konzelmann meets these demands with consistent material and design validation and has already developed purkon®2000, a TÜV-certified material designed for these extreme conditions.

Would you like to learn more about Konzelmann’s customized TPU materials or are you interested in an interview? Please contact our press office.

Further links:

•

Konzelmann TPU seals for e-mobility - AI Online –

Advantages of TPU

The injection molding process for TPU enables properties that cannot be achieved with conventional seals made of metal, rubber-metal or PTFE:

•

Implementation of complex geometries

•

Short production cycle times

•

Lightweight design potential through the substitution of heavier components

•

Simplified assembly thanks to flexible, installation-friendly geometries

“Thanks to our experience with complex sealing applications and the highly robust TPU material, we are able in some cases to replace a complicated metal or rubber-metal sealing solution with a pure TPU solution – achieving noticeable weight reduction while simultaneously optimizing vehicle performance,” explains Heiko Kurz, Head of Sealing Technology Business Unit at Konzelmann.

Focus on sustainability

Konzelmann pursues a clear sustainability approach with TPU. Wherever technically feasible, materials are developed using renewable raw materials – such as castor oil. Results are continuously validated in the company’s own chemical laboratory. At the same time, Konzelmann completely avoids prohibited substances or PFAS.

“For us, thermoplastic polyurethane (TPU) is a biogenic high-performance material class that not only convinces ecologically but also represents a superior alternative to conventional plastics,” emphasizes Heiko Kurz.

New applications in mobility

Alternative drive concepts are opening up new application possibilities for TPU: in electric and fuel cell vehicles, operating temperatures are significantly below the maximum continuous temperature of 110°C. This allows TPU seals to be used in areas where they were previously unsuitable due to thermal stress.

Outlook: Hydrogen technology

Applications in the hydrogen sector with pressures up to 1,050 bar and temperatures down to −60°C are particularly challenging. Konzelmann meets these demands with consistent material and design validation and has already developed purkon®2000, a TÜV-certified material designed for these extreme conditions.

Would you like to learn more about Konzelmann’s customized TPU materials or are you interested in an interview? Please contact our press office.

Further links:

•

Konzelmann TPU seals for e-mobility - AI Online –

Downloads

Contact for press inquiries

Press contact Press office Konzelmann c/o follow red GmbH Dimitra Malama

Waldburgstraße 17/19 70563 Stuttgart Germany Tel.: +49 (0)173 2835973 E-mail: [email protected]

The images provided can only be used in connection with reporting on Konzelmann, quoting “Photo: Konzelmann”.

Waldburgstraße 17/19 70563 Stuttgart Germany Tel.: +49 (0)173 2835973 E-mail: [email protected]

The images provided can only be used in connection with reporting on Konzelmann, quoting “Photo: Konzelmann”.

Further press releases of the exhibitor

E-Mobility - Safety Simplified – Intelligent Safety Solutions for Battery Systems

Polymer Expertise - “Innovation meets Polymer” – Polymer Expertise that Drives Change

PRESS KIT – Company Profile - Global Expertise, Swabian Roots – Konzelmann in Portrait

PRESS KIT – Introduction - Innovation meets Polymer – Konzelmann at IAA MOBILITY 2025

◦

◦

◦

◦